Sheet Polymer Stamp Making Machine

MOQ : 1 Piece

Sheet Polymer Stamp Making Machine Specification

- Product Type

- Stamp Making Machine

- General Use

- Stamp Manufacturing

- Material

- Mild Steel & Polymer

- Type

- Sheet Polymer Stamp Making Machine

- Capacity

- 200 Stamps/Day

- Weight (kg)

- 30 kg

- Computerized

- No

- Automatic

- No

- Control System

- Semi-Automatic

- Stamping Plate Size

- A5 (148 mm x 210 mm)

- Stamping Power

- Manual

- Stamping Speed

- 150 Stamps/hour

- Stamping Temperature

- 100C - 120C

- Power Consumption

- 500 W

- Plate Type

- Polymer Plate

- Working Temperature

- Up to 120C

- Heating Power

- 400 W

- Voltage

- 220 V AC

- Dimension (L*W*H)

- 520 mm x 380 mm x 310 mm

- Feature

- Easy Operation, Low Maintenance

- Color

- Blue & Silver

- Cooling System

- Passive Air Cooling

- Working Speed

- 150-200 stamps/hour

- Installation

- Plug & Play

- Power Supply Frequency

- 50 Hz

- Service Support

- Onsite Support Available

- Heating Element Type

- Ceramic

- Safety Features

- Overheating Protection

- Operation Method

- Manual Operation with Heating Control

- Application

- Rubber, Polymer & Photopolymer Stamp Making

- Display

- Digital Timer Display

- Noise Level

- Low

Sheet Polymer Stamp Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Against Delivery (CAD), Cash on Delivery (COD), Delivery Point (DP), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5 Pieces Per Day

- Delivery Time

- 3 Days

- Main Export Market(s)

- Middle East, Africa, Asia

- Main Domestic Market

- All India

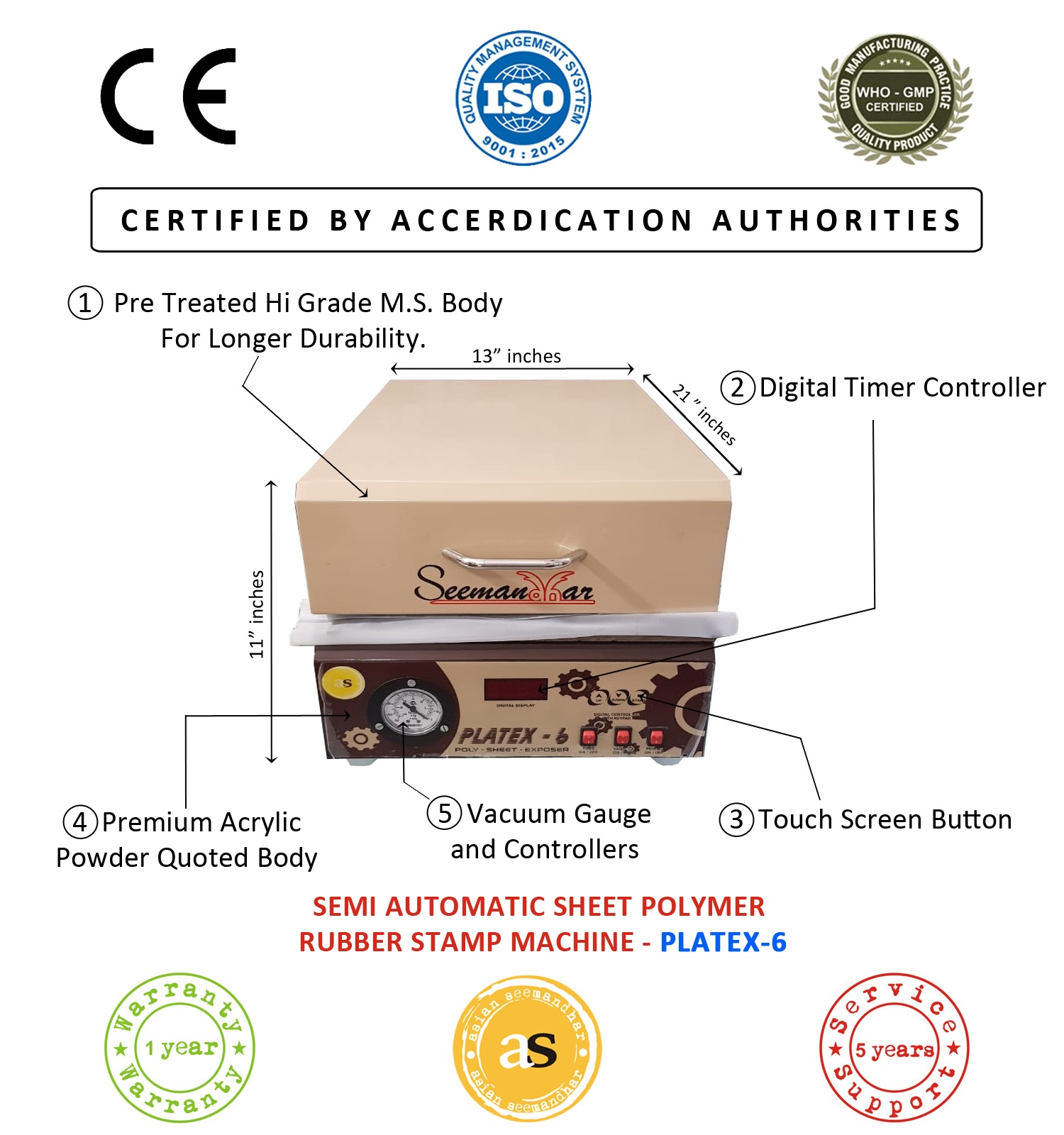

About Sheet Polymer Stamp Making Machine

Grab this sizzling Clearance offer on our top-ranking Sheet Polymer Stamp Making Machine! Crafted with champion-grade materials like mild steel and polymer, this top-notch machine boasts a digital timer display, ceramic heating elements, and advanced overheating protection. Designed for rubber, polymer, and photopolymer stamp making, it operates with low noise and passive air cooling. Its plug & play installation, easy manual operation with heating control, and onsite support make it a hassle-free addition for any stamp manufacturing business in India. Grab yours now!

Superior Features & Versatile Applications

The Sheet Polymer Stamp Making Machine is engineered for efficiency and reliability, making it ideal for use in rubber, polymer, and photopolymer stamp production. Its manual operation with heating control supports up to 200 stamps per day, catering perfectly to business, office, and institutional needs. With a working temperature of up to 120C and low maintenance requirements, this machine is a preferred choice at commercial stamp manufacturing sites across India due to its robust build and safety features.

Outstanding Supply, Export Reach & Quick Dispatch

Our Sheet Polymer Stamp Making Machines are always ready for prompt dispatch thanks to strong supply ability and careful packaging that ensures product safety during shipping. Samples are available upon request, and shipments are expertly managed to meet deadlines for both domestic and international clients, making us a trusted manufacturer and supplier in India and key export markets. With every order, reliability and speedy delivery are championed from dispatch to arrival at your location.

Superior Features & Versatile Applications

The Sheet Polymer Stamp Making Machine is engineered for efficiency and reliability, making it ideal for use in rubber, polymer, and photopolymer stamp production. Its manual operation with heating control supports up to 200 stamps per day, catering perfectly to business, office, and institutional needs. With a working temperature of up to 120C and low maintenance requirements, this machine is a preferred choice at commercial stamp manufacturing sites across India due to its robust build and safety features.

Outstanding Supply, Export Reach & Quick Dispatch

Our Sheet Polymer Stamp Making Machines are always ready for prompt dispatch thanks to strong supply ability and careful packaging that ensures product safety during shipping. Samples are available upon request, and shipments are expertly managed to meet deadlines for both domestic and international clients, making us a trusted manufacturer and supplier in India and key export markets. With every order, reliability and speedy delivery are championed from dispatch to arrival at your location.

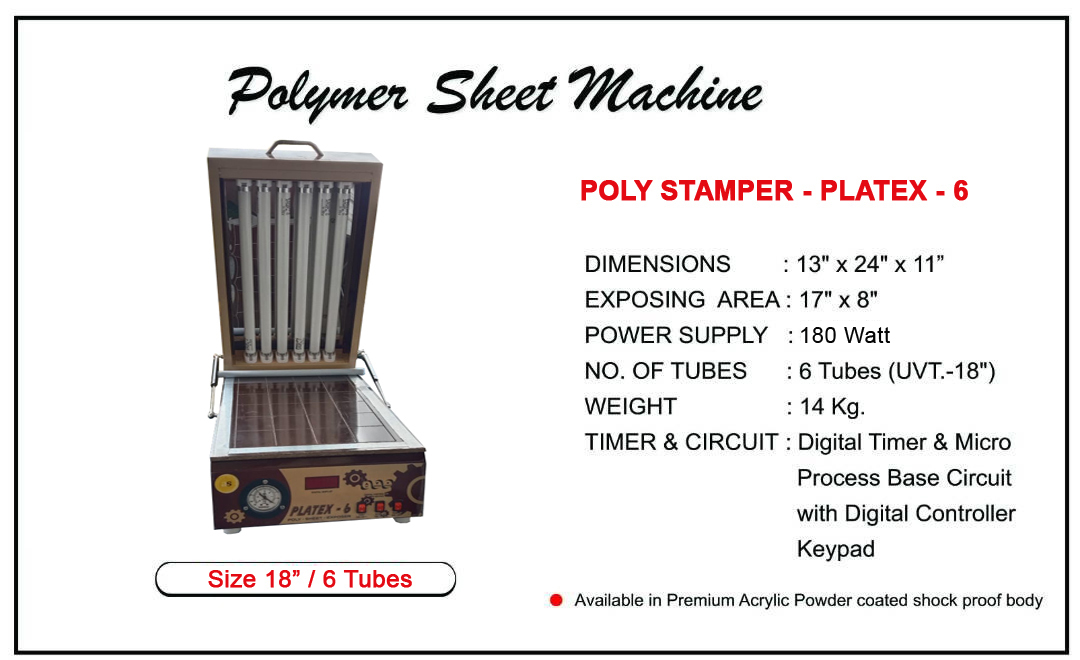

Specification

|

Capacity Production Capacity Model Automation Grade Grade Brand Voltage Power Poly Stamper Dimensions Exposing Area Power Supply |

1 to 150 stamps per hour 1 to 150 Stamp per hour Sheet polymer platex-6 Semi Automatic A Seemandhar 180 watt,16 Volt 230 AC platex-6 13" X 24" X 11" 17" X 8" 230 AC 6 Tubes (UVT: 18") Digital Timer & Micro Process Base Circuit with Digital Controller Keypad 14 Kg |

|

No Of Tubes Timer And Circuit Weight |

FAQs of Sheet Polymer Stamp Making Machine:

Q: How do you operate the Sheet Polymer Stamp Making Machine?

A: The Sheet Polymer Stamp Making Machine features a manual operation method with easily adjustable heating control. Simply plug in the unit, set your desired temperature using the digital timer display, and load the polymer plate. The process is straightforward, with prompt onsite support available if needed.Q: What applications is this machine suitable for?

A: This machine is designed for the efficient manufacturing of rubber, polymer, and photopolymer stamps. Its widely used in businesses, offices, institutions, and commercial stamp production setups where robust performance and reliability are required.Q: Where can the Sheet Polymer Stamp Making Machine be installed?

A: Installation is convenient at any commercial site with basic infrastructure. Thanks to its plug & play setup and passive air cooling, it fits comfortably into workshops, printing shops, or institutional environments without complex installation requirements.Q: What are the benefits of using a ceramic heating element in this machine?

A: Ceramic heating elements provide fast, even heat distribution, ensuring precise stamp quality and energy efficiency. This also helps in maintaining low power consumption and avoids overheating, making the machine durable and safe to use over long periods.Q: How many stamps can be produced daily with this machine?

A: The machine boasts a working speed of 150200 stamps per hour, with a daily production capacity of up to 200 stamps, making it extremely productive for medium to large-scale operations.Q: What make this machine a top-ranking choice for stamp manufacturers?

A: Its combination of a champion build, digital timer, ceramic heater, overheating protection, low noise operation, and onsite service support positions it as a top-notch, reliable solution for stamp making businesses looking to enhance production quality and consistency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry